Graphene based electromagnetic compatibility material

To replace materials used to ensure electromagnetic compatibility towards a more environmentally friendly and recyclable alternative.

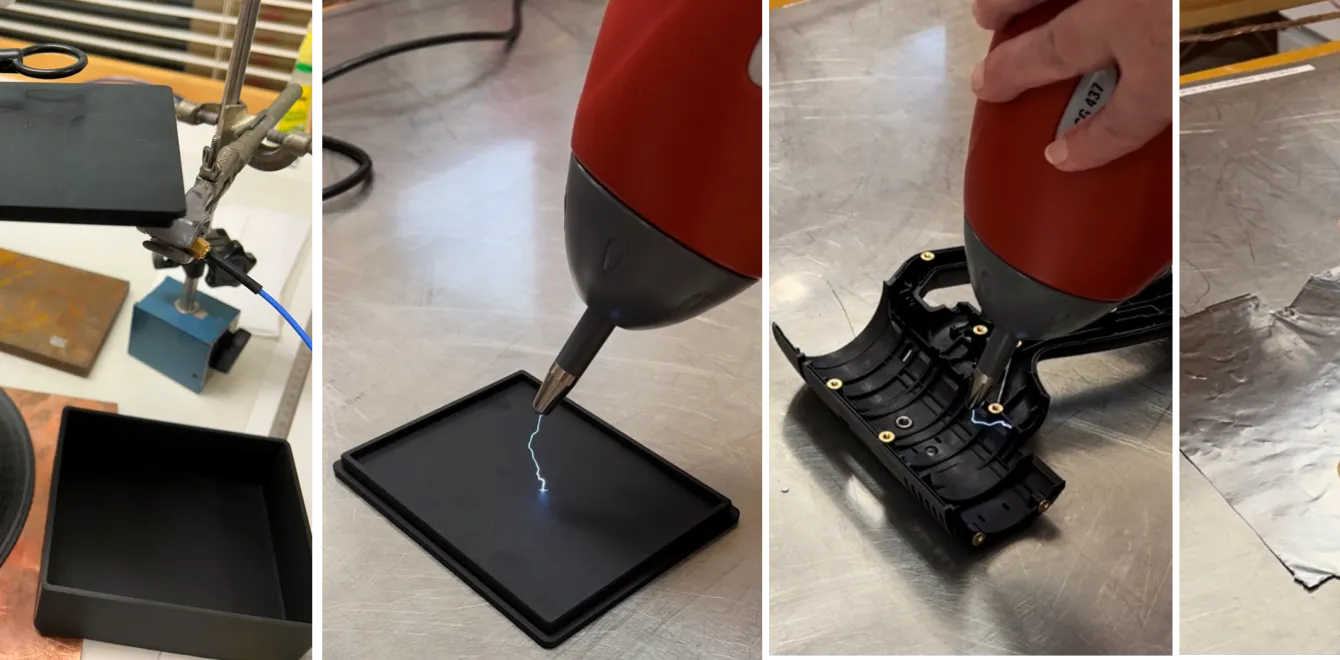

The project aims to replace current metal-based materials with graphene-based materials to ensure electromagnetic compatibility (EMC) function in industry towards a more environmentally friendly and recyclable alternative. The method proposed in this project is based on circular economy. RISE IVF proposed materials to be tested are to mix the graphene with current plastic or bioplastic into composites and follow with injection moulding into products. These proposed graphene-based composites would be bio-based and recyclable. And the EMC shielding materials mainly nickel and aluminium, will be replaced by graphene. Participants in the project are partly manufacturers of graphene such as Meva Energy AB and Graphmatech AB. The bioplastic manufacturer is Biofiber tech AB. The end users are Atlas Copco Industrial Technique AB and Megger Sweden AB. For evaluation of electrical properties, EMC Services and RISE IVF shall perform a comparative test between the produced graphene-based material and current conductor, and partly on product level where a handle for products of Atlas shall be tested in an EMC -LAB.

Biochar from biobased syngas producer Meva Energy AB has the potential to be an energy smart and biobased source of graphene. In this project, the biochar has been ball-milled into sub-microparticles. Fraction of graphene was detected but further refinery needs to be used to increase the concentration for commercial use.

Biofiber Tech AB recognizes the immense market potential of incorporating graphene into natural/wood fiber composites in industries such as electronics, aerospace, and automotive to achieve a sustainable bio-based economy. As part of this initiative, BFT has utilized their unique patented technology to surface modify graphene (used as conductive additive) together with their wood fibers (FibraQ). The resulting "graphene-modified wood fiber” was then compounded at RISE into a biobased composite for a range of application cases. Graphene is a novel type of nano-sized two-dimensional conductive additive that demonstrated a unique potential to facilitate conductive properties on wood fiber during the FibraQ process. However, the commercialization of such materials presents significant challenges, including the cost, dispersion, and environmental impact of graphene sources. Furthermore, the graphene-based conductive biocomposite requires a thorough life cycle analysis to better understand the material's CO2 emission equivalent and identify suitable applications that can replace fossil-based materials.

User case 1 : Atlas has dedicated to finding sustainable solutions to realize circularity in all products. This project used graphene in prototypes and compared the EMC performance of various conductive materials. Bio-based composite prototype has also been manufactured and tested. Atlas will continue the research to further realize its sustainability goal.

Use Case 2: Megger has similar requirements to Atlas for EMC materials. To reduce the use of metal and product weight. The potential to use graphene in production is determined by the material cost and the potential to optimize EMI attenuation to meet the EMC standard.

Summary

Project name

SIO Grafen EMC

Status

Active

RISE role in project

Projektledare

Project start

Duration

24 månader

Total budget

2 880 000