Contact person

Analysing cellulose

The analysis of cellulose in pulp mills is crucial for efficient operations and high-quality pulp production. One of the most important factors is the raw material – the wood.

What is cellulose?

Cellulose is a natural polysaccharide forming the main component of plant cell walls and is the most abundant organic compound on Earth. It is primarily used in the paper and textile industries and as a sustainable raw material for bio-based products.

Pulp product analyses

To ensure pulp of satisfactory quality, precise fibre and pulp analyses are essential. The following measurements are offered:

Physical properties: beating degree (°SR/CSF), WRV, sheet, basis weight, thickness, density/bulk, strength, and air permeability.

Chemical analyses: carbohydrates, extract content, phenolic groups, fibre charge, kappa number, metals, viscosity, and leachable COD/TOC.

Wood and biomass feedstock

Wood and biomass feedstock characterisation involves analysing chemical composition, structure, and physical and mechanical properties:

Basic parameters: dry content, size distribution, bark content, density, thickness and distribution, fibre dimensions.

Chemical analyses: metals (e.g. calcium, copper, iron, zinc), carbohydrates, lignin, extractives, ash content, organic chlorine, oxalic acid, carbonyl end groups, uronic acids.

Physical properties: viscosity, fibre charge, fibre length and wall thickness, conductivity, pH.

Specific tests: alkali resistance, molecular weight distribution, wash loss, leachable COD/TOC, Kappa number, Fock’s reactivity, hexanal.

We also perform wood and pulp analyses, including alpha, beta and gamma cellulose, as well as contaminants such as stains and dirt.

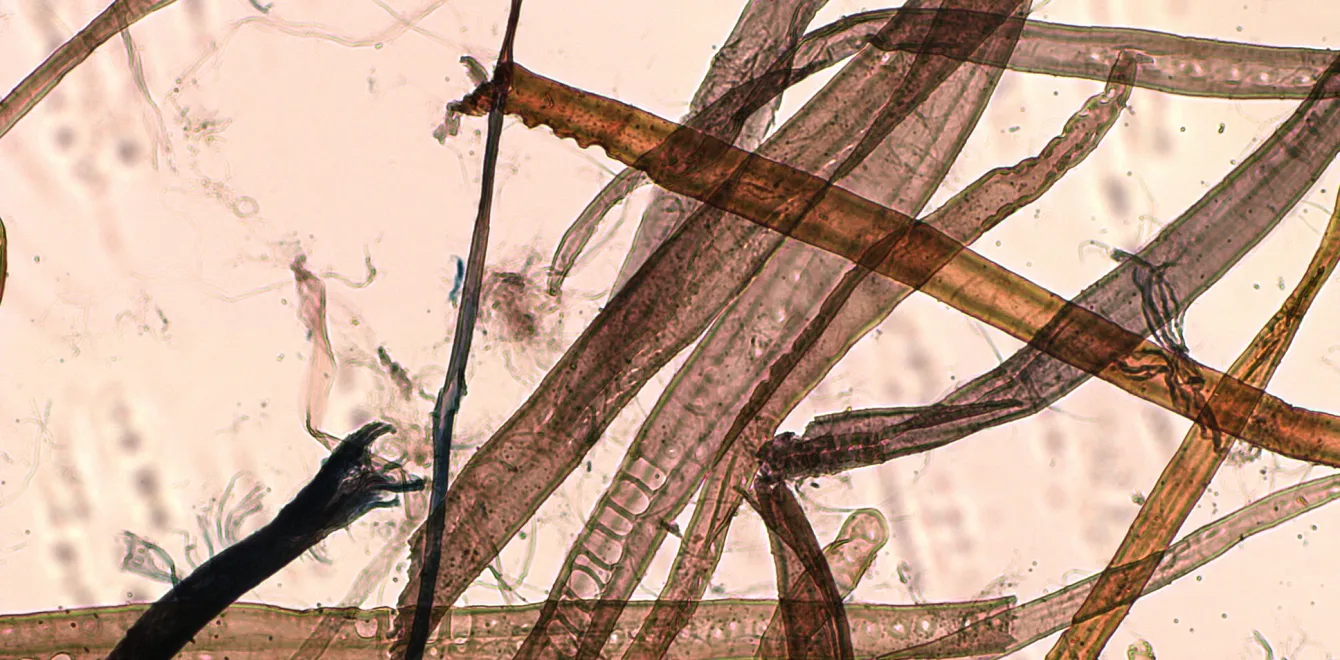

Fibre dimensions

Fibre analysis is a vital process in the pulp and paper industry, offering valuable insight into pulp composition and properties.

By examining fibre length, diameter, curl, coarseness and other key parameters, the performance and suitability of the pulp for various applications can be accurately assessed.

Analyze fillers in cellulose

RISE provides evaluation of fillers in paper products, focusing on critical parameters. We assess key properties such as brightness, pH, dryness and viscosity to determine the quality and suitability of fillers for various paper applications.