To develop, optimize the pulp process, testing and characterization of the pulp is important. Partly to know which properties are affected when process conditions change.

Purpose

Grinding pulp for sheet and testing gives a good overview of the end product's important properties for good quality. Evaluation of the fiber composition or the effect of milk chemistry is also possible. See RISE opportunities below. It is also possible to order mapping in use to follow important parameters.

Method

Refinery

Pulp properties

- Beating Degree SR°/Freeness CSF

- Dewatering ability, DDA

- Water retention value, WRV

Prepararion of the pulp

- Pulp concentration

- Standard water/deionized water / distilled water/MilliQ water

- Dry content determination

- Disintegration

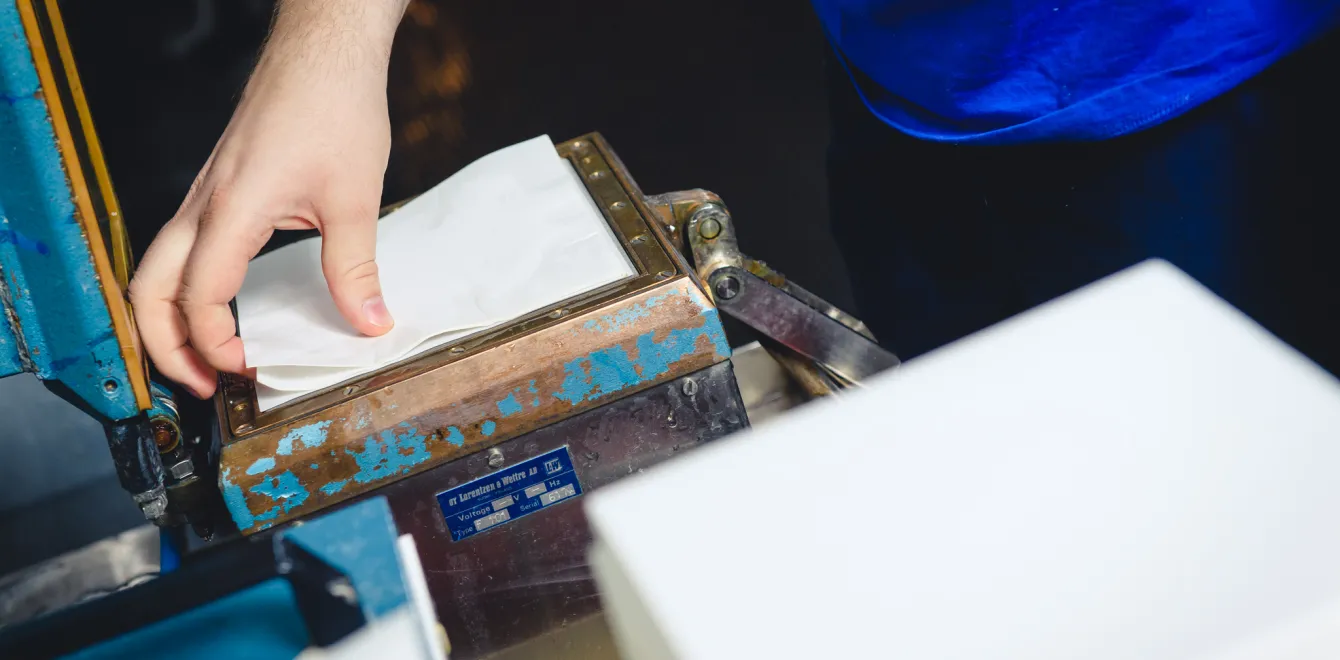

Laboratoriearkning

- Conventional sheet former

- Rapid Köthen sheet former

Egenskaper på handark

- Grammage

- Thickness, bulk och density

- Tenslie strength properties

- Brightness

-

- Air permanence/porosity, Bendtsen

- Air resistance, Gurley

- Burst strength

- Tearing resistance

Optical properties

- ISO-Brightness

- Whitness CIE, ASTM E313

- Light scattering coefficient, s

- Light absorption coefficient, k

Fiber contribution

Bauer McNett, fiber fractions

BrittJar, fines

Somerville, shives - screening of pulp stickies, plastics, sand, metal pieces, and flakes in recycled fiber.

Fiberdimensioner

- Fiber length

- Fiber width

- Fiberform, curl

- Fine material

- Fiber weight, coarsness

- Spethalt

- Fiber length distribution

- Kinks

- Pictures, fibers and lace

Purities

- Dirt and tip

- Assessment of dirt and lace in sheet-dried pulp with transillumination

- Dirt in mass

- Stone cells

Permanence

- Accelerating heat aging 105 ° C / 100 ° C

- Accelerating aging 80 ° C 65% moisture

- Accelerating heat aging 120 ° C or 150 ° C

- Accelerating aging when exposed to light

- Brightness Aging in Health Test Cabinet (Xenon Light)

Meld chemistry

- Ash 525 ° C / 900 ° C

- Cation demand

- Retention studies, Britt Jar, DDA

- Turbidity

- Z-potential

Deliveries

Report